eFuels are inefficient – this myth is probably the most widespread argument against the use of power-to-liquid (PtL) fuels.

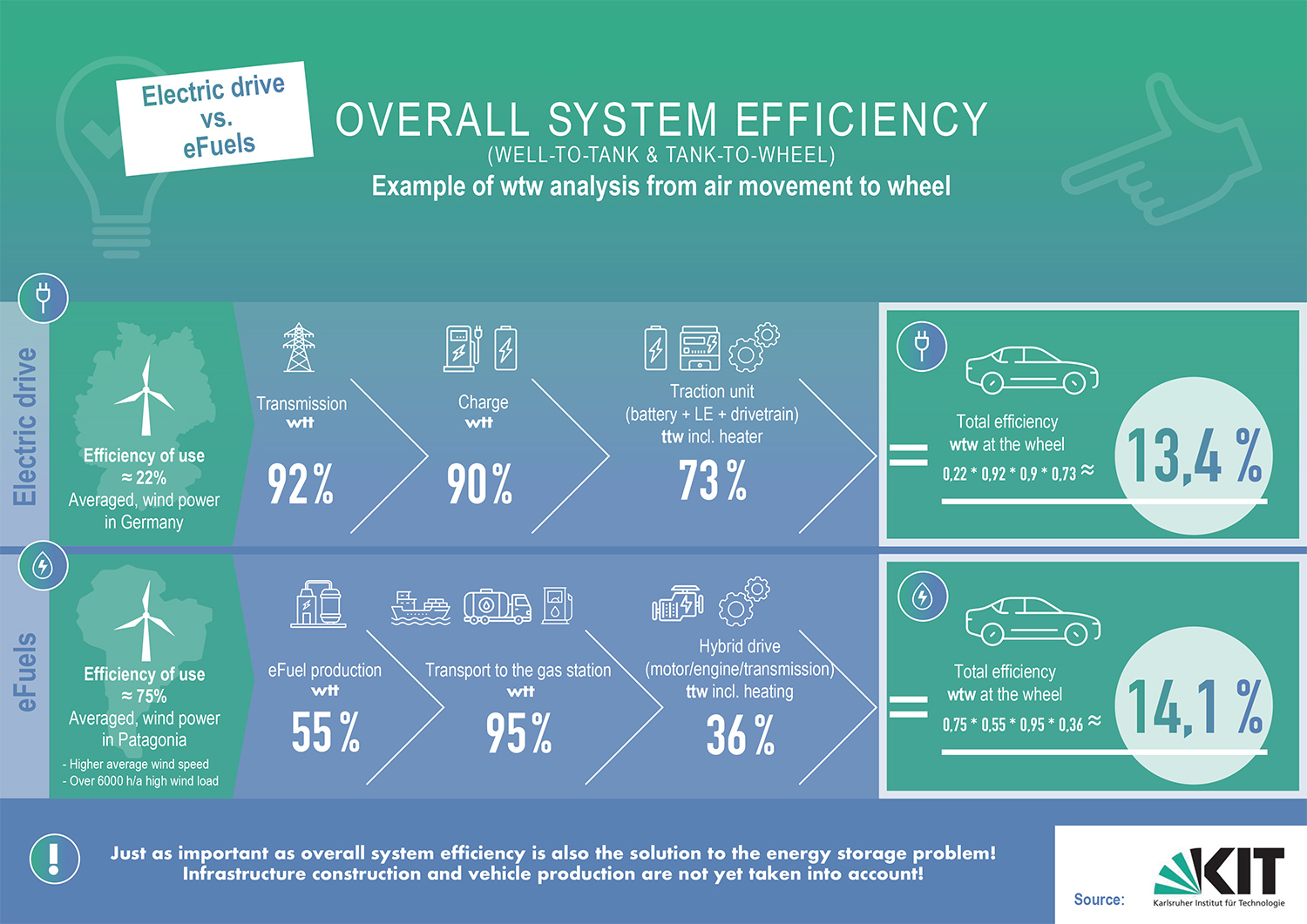

Most efficiency considerations only refer to the electric motor without considering the overall system before and after the motor. Moreover, they are based on the unrealistic assumption of industrial eFuels production in Germany. However, the analysis of system efficiency must always be based on realistic and holistic assumptions. The KIT graph depicts this overall system efficiency. Here, the electric car is compared with a combustion vehicle that is operated with eFuels.

Important: The system efficiency extends from the wind gust to the turning wheel (well-to-wheel, wtw) and not only from the engine to the wheel (tank-to-wheel, ttw). This is because an electric car cannot run without pre-transformed electricity. The torque of the electric motor must also be transmitted to the wheels.

When considering overall system efficiency, it is important where the green electricity is produced. Either an electric car runs on inefficient German green electricity. Then the high efficiency of the electric motor offsets the losses of electricity production. Or Germany imports green energy from regions where green electricity can be “harvested” very efficiently. In both cases, the overall system efficiency is at a similar level.

Photovoltaic electricity achieves a usage efficiency of only 10.5 percent in Germany. In sunny MENA countries (Middle East and North Africa) such as Morocco and Algeria, the utilization efficiency is twice as high.

The situation is similar for wind power: In Germany, wind turbines achieve an average utilization efficiency of around 22 percent. At the North Sea, the figure is slightly higher at around 30 percent, while in southern Germany it is somewhat lower at around 17 percent. In contrast, a wind turbine at the “Haru Oni” hydrogen plant in Patagonia/Southern Chile achieves around 75 percent with an average of 270 days per year at full load, or 6,480 full load hours. Please also read > Because the wind there is so strong that even the trees grow crooked.

Photovoltaics alone could meet the energy needs of the entire planet on a very small footprint. This green electricity then only needs to be made transportable and storable. This is done by first converting the electricity into hydrogen and then producing eFuel from it by adding CO2.

This explains the name of the synthetic fuel: electro based fuel. eFuels, as a hydrogen derivative, are therefore nothing more than liquefied and thus transportable green electricity. It would also be possible to transport the hydrogen itself. But this is very expensive, because hydrogen must be cooled and kept under pressure. Moreover, as the lightest element on earth, hydrogen diffuses quickly through transport pipelines, which poses a further problem.

Ultimately, therefore, it is not so important how efficient eFuels are in production. They only need to be produced where there is no shortage of renewable energy and clean drinking water. Please also read >

The efficiency issue can also be viewed from a different angle: In terms of cost, time and resource efficiency, it makes most sense to make the existing vehicles and infrastructure CO2-neutral.

In contrast to electromobility, everything is already there. Over 99 percent of the world’s approximately 1.4 billion cars are gasoline or diesel-powered.

Reducing CO2 emissions from the existing fleet is therefore the biggest and fastest contribution to global climate protection in the transport sector.

In contrast, electromobility requires a completely new infrastructure with high resource requirements and a correspondingly high CO2 footprint (CO2 backpack). Furthermore, the construction of heavy electric cars requires additional resources such as mineral raw materials (lithium, cobalt, copper, nickel, graphite, silicium, gallium) and rare earths, which are listed by the EU as “critical raw materials” and of which there are only a few suppliers worldwide, which calls into question the permanent security of supply and can lead to dependencies.

After all, Germany has a very large energy import requirement of 70 percent, so green molecules have to be imported in the form of fuels anyway. The liquid form is necessary because of the high energy density, because only then the transport distance is practically irrelevant (high transport efficiency). Once the green molecules are in the country, it is more efficient to use them directly in electricity-independent systems such as internal combustion engines and oil-fired heating systems instead of first converting them into electricity with high losses and, if necessary, storing them temporarily in batteries with further losses.

SYNTHEC FUELS production plants with their numerous and sustainable recycling of organic waste fractions can therefore make a significant contribution to regional energy production, security and CO2 reduction anywhere in the world.