The SYNTHEC FUELS Solution

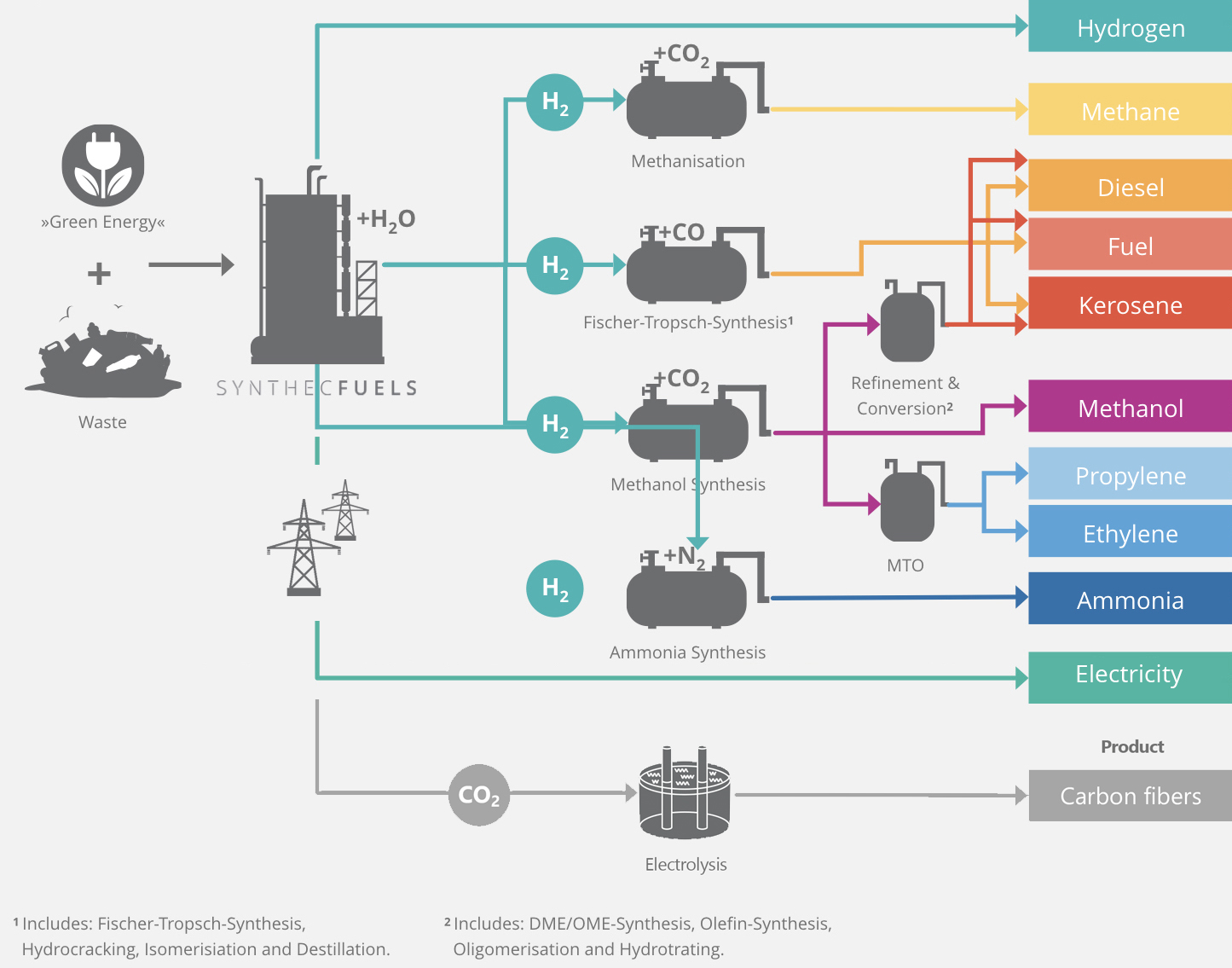

Processes for the Conversion of Waste and CO2 into sustainable Products

- Holistic recycling of all components contained in the input raw materials producing sustainable green hydrogen, CO2 -neutral synthetic fuels, industrial gases and fertilizers.

- Consumption of only 0,2 litres Water per 1 kg sustainable hydrogen produced, compared to a consumption of 9,0 litres drinking water per 1 kg Hydrogen if produced via electrlyzer

- Drastic reduction of emissions (particulates, SOx, NOx) by use of Synthec Fuels’ high-quality, clean, CO2-neutral and sulphur-free fuels, especially for diesel vehicles (cars, trucks, buses, ships, diesel locomotives, aircraft, etc.)

- Highest flexibility in non-recyclable problematic feedstocks (sewage sludge, manure, biomass, organic waste , plastics, incl. PVC and residuals) either wet or dry.

- Comprehensive CO2 mitigation concept, converting the CO2 from the process into green hydrogen, synthetic fuels, methanol or methane as well as in solid materials like e.g. synthetic coal and carbon fibres

- Synthec Fuels’ production costs for green hydrogen are today at the level that the European Commission has set as a target for the production costs for the year 2050

- Using innovative “state-of-the-art” technologies that are already operational at industrial scale

- Fully self-sustaining system powered by waste

- Plant availability: 7.500 full load hours per year (incl. scheduled maintenance)

- Scalable to meet every requirement – no up-scaling limit due to modular concept; down-scaling to as little as 16.000 metric tons of feedstock p.a.

- Recovery of valuable materials from landfills as source for feedstocks for the Synthec Fuels process